One of the most frequently asked questions by buyers when choosing acoustic panels is:

Are thicker acoustic panels better?

In short, the answer is yes—but not always in the way people expect.

Panel thickness does affect sound absorption, but it's only one part of the overall acoustic performance. In this article, we'll explain how thickness works, when thicker panels are more beneficial, and how to choose the right solution for your space.

How Acoustic Panels Absorb Sound

Acoustic panels reduce echoes and reverberation in a room by absorbing sound energy, especially mid-to-high frequency sound waves.

Key factors affecting performance include:

Panel thickness

Material density

Surface design

Installation method

Air gap behind the panel

Thickness alone does not guarantee better results.

Does thickness really improve sound absorption?

Yes—especially for low frequencies.

Generally speaking:

Thicker panels can absorb a wider frequency range.

They are more effective at low frequencies than thinner panels.

For example:

12-25 mm thick panels primarily absorb high frequencies.

40-50 mm thick panels absorb mid-frequency frequencies more effectively.

Thick panels with backing systems help control low-frequency energy.

However, for everyday residential and commercial spaces, ultra-thick panels are often unnecessary.

Thicker with Smarter Design

Modern acoustic solutions are not simply about increasing thickness, but about balancing design.

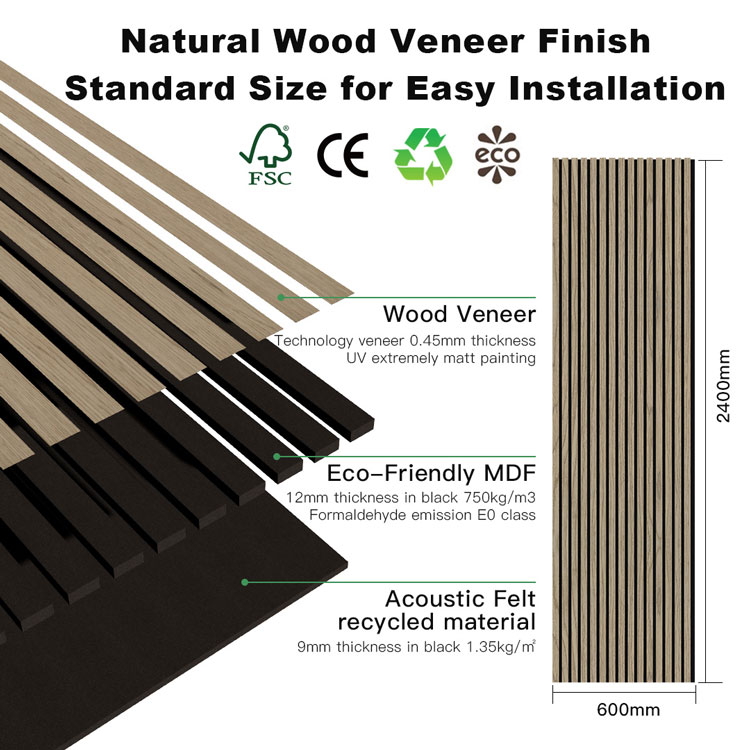

For example, wood slat acoustic panels use:

Rigid medium-density fiberboard slats for sound diffusion

High-density polyethylene terephthalate (PET) felt for sound absorption

Thickness optimized for the actual space

This combination achieves effective acoustic control without adding excessive volume or visual clutter.

When to Need Thicker Acoustic Panels

Thicker acoustic panels are best suited for:

Recording studios

Music rehearsal rooms

Home theaters

Large open-plan commercial spaces

In these environments, low-frequency control is crucial.

When Thicker Acoustic Panels Are Not Needed

For example:

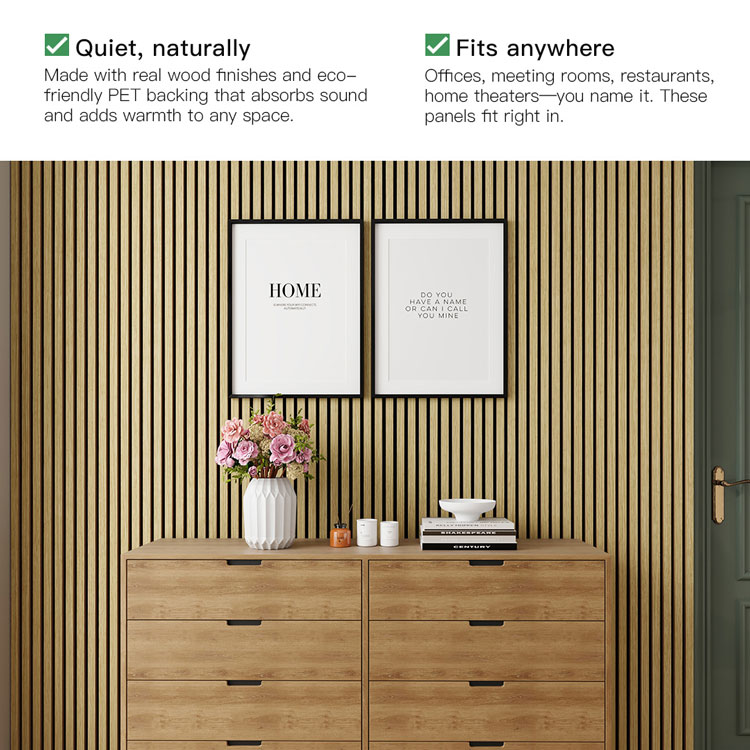

Living rooms

Bedrooms

Offices

Conference rooms

Restaurants and hotels

Standard-thickness acoustic panels or wood strip acoustic panels, if installed properly, already provide excellent sound absorption.

In these cases, installation location and coverage are more important than thickness.

The Role of Air Gap (Often Overlooked)

An important professional insight:

Adding an air gap behind the acoustic panel can significantly improve low-frequency absorption—sometimes even better than increasing thickness.

This is why wall-mounted wood strip acoustic panels with felt backing are so effective in actual installations.

Why Wood Strip Acoustic Panels are the Ideal Balanced Choice

Wood strip acoustic panels offer the following advantages:

Moderate thickness, suitable for most environments

Natural sound diffusion and absorption

Aesthetically pleasing, perfectly complementing modern interior design

Highly effective sound absorption without excessive space occupation

Achieving an ideal balance between functionality, design, and ease of installation