Living in an apartment often means enduring various noises—neighbors' conversations, TV noise, footsteps, and even echoes in your own room. This leads many renters and landlords to ask:

Is it worth installing acoustic panels in an apartment?

The answer is yes—provided they are used correctly. While acoustic panels cannot completely block out noise, they can significantly improve comfort, clarity, and overall sound quality. In this guide, we'll explain the role and limitations of acoustic panels in apartments, and why they are a smart upgrade for modern urban living.

Common Noise Problems in Apartments

Apartment buildings typically have the following characteristics:

Shared walls and ceilings

Hard surfaces such as concrete and drywall

Limited finishing options

This often leads to:

Echoes and reverberation within rooms

Poor speech intelligibility

Noise easily propagates throughout the space

Constant background noise increases stress

Acoustic treatment can solve many of these problems without altering the building structure.

The Practical Role of Sound-Absorbing Panels in Apartments

Sound-absorbing panels are designed to absorb sound reflections, not completely block sound.

In apartments, sound-absorbing panels serve several purposes:

Reducing echoes and reverberation

Improving speech and television clarity

Making rooms feel quieter and more comfortable

Minimizing noise from neighbors

Preventing sound reflections within the room

While they are not a complete soundproofing solution, they can significantly improve the quality of daily life.

Sound-Absorbing Panels vs. Soundproofing: What Apartment Owners Need to Know

Understanding the difference is crucial:

Sound-absorbing panels → Improve sound quality in the apartment

Soundproofing → Prevent sound from entering or leaving the apartment

True soundproofing requires extensive construction and structural modifications, which is often impractical in apartments. Sound-absorbing panels, on the other hand, are a non-invasive, effective, and renter-friendly option.

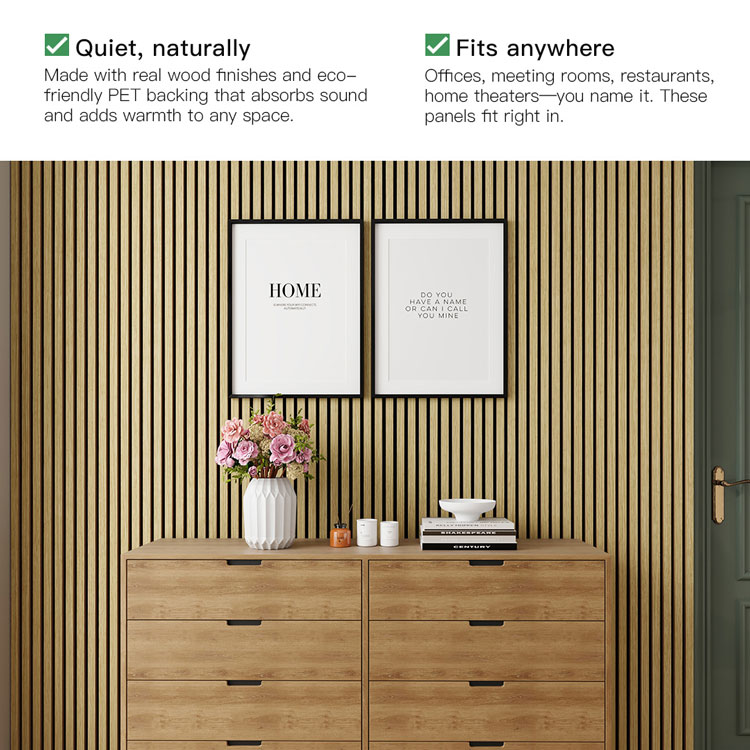

Why Wood Strip Sound-Absorbing Panels are Ideal for Apartments

Wood strip sound-absorbing panels are particularly popular in apartments due to their combination of performance and aesthetic design.

Advantages of using acoustic panels in apartments:

Effectively absorbs mid-to-high frequency noise

Reduces echoes in living rooms and bedrooms

Adds warmth and visual depth to interior spaces

Suitable for modern, minimalist, and luxury designs

Requires no major renovations for installation

Especially suitable for behind TVs, shared walls, and home office or bedroom spaces.

Installation Locations for Apartment Acoustic Panels

For best results, focus on the following problem areas:

Shared walls with neighbors

Behind TVs or entertainment systems

Home office or study areas

Bedroom walls near noise sources

Strategic installation is generally more effective than covering the entire room.

Are acoustic panels worth installing for renters?

Yes. Many modern acoustic panels:

Require only a few holes for installation

Removable and reusable

Won't damage walls when installed correctly

Therefore, they are an excellent choice for renters who want to improve acoustics without making permanent modifications.